PD Series Pool De-Humidifier

Our PD Series of Pool Dehumidifier units cool, dehumidify and reheat air from pool areas. They can also incorporate heat recovery of the exhaust air for additional operating cost savings.

PD Series

Indoor / Outdoor Pool De-Humidifiers

Features

- Indoor or outdoor models are available

- Corrosion resistant Heresite coating is used on DX cooling and condenser coils

- Compressor energy (heat) is reclaimed and used to heat pool water

- Latent heat loss from the pool a water evaporates is reclaimed and rejected back into pool water and the pool supply

- Auxiliary remote air cooled condensers are available which allows the system to provide space air conditioning

- A variety of control options are available

Options

- Return air fans and/or mixing boxes can be provided when required.

- Auxiliary Engineered Air heating components (DJ, DG, electric, water, or steam coils) can be added to give a complete package.

- Free cooling packages including motorized dampers (outside air, return air and exhaust air), as well as all economizer controls are available.

- Whirlpool de-superheaters (selected for higher pool water temperature) are available.

- Exhaust air heat reclaim systems using air to air, or heet pipe coils air available.

Benefits

Evaporating from the surface of an indoor swimming pool causes two major concerns. The first and most obvious problem relates to the resulting high relative humidity level.

During periods of low outside air temperatures, high indoor humidity causes problems with condensation and frost on windows.

A more serious problem could result if moisture penetrates into the building structure, where it could condense and freeze thereby causing structure damage.

The second major concern is heat loss from the surface of the swimming pool. As moisture evaporates from the surface of the pool, a large amount of heat is lost as the latent heat of evaporating is carried away by the moisture. If the humid air was simply exhausted, all of this latent heat would be lost and would have to be replaced by heating the pool water.

This discussion makes the benefits of an Engineered Air PD Series pool de-humidifier obvious. These benefits can be summarized as follows:

- Reduced pool heating costs due to reclamation of latent heat of evaporating from pool surface.

- Reduced space humidity levels prevents possible structural damage due to condensation.

- Space comfort conditions are also obviously improved by the lower relative humidity level. If a remote (outdoor) air-cooled condenser is used, the resulting space cooling ability also has obvious benefits.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

CD Series Ice Rink De-Humidifiers

CD Series

Ice Rink De-Humidifiers

Application

A common problem encountered in skating or curling rinks is fog and / or moisture condensing and dripping from the structure. This occurs during periods when the space temperature is low and moisture content of the air relatively high. Condensation problems can occur throughout the year but more frequently occur during the spring and fall seasons.

In pool environments, outside air can often be used to condition the space and reduce the moisture level. This approach cannot be used in a rink environment because the outdoor air contains moisture with a higher dewpoint level than the indoor temperature of the rink. As a result, bringing in outdoor air for ventilation only adds to the fog and condensation problems.

The solution is to remove moisture from the ice rink air by using an Engineered Air dehumidifier. Our CD Series is one option. One alternative is the DWD Desiccant Gas Fired De-humidifier by Engineered Air.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

SH Series Commercial - Industrial Gas Fired Steam Humidifier

Dedicated Engineered Air controls, specifically designed for EngA Burners, are used to achieve up to 15:1 fully modulating turndown ratio. The ability to modulate the combustion process, while maintaining or increasing the efficiency throughout the turn down range, results in the lowest energy cost per pound of steam produced.

This recognized combination of Engineered Air TRAC controller, burner and heat exchanger is further enhanced to achieve minimum capacity duration at high altitudes.

These proven technologies are the heart of the Engineered Air SH Gas Fired Humidifier. Learn More

SH Series

Commercial - Industrial Gas Fired Steam Humidifier

Features

- Up to 650 pounds of steam per hour

- Engineered Air Combustion Technology

- Up to 15:1 fully modulating turndown ratio

- High efficiency heat exchangers

- Low profile arrangement

- Large tank for less interruption

Typical Options ( * ) represents standards features

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.

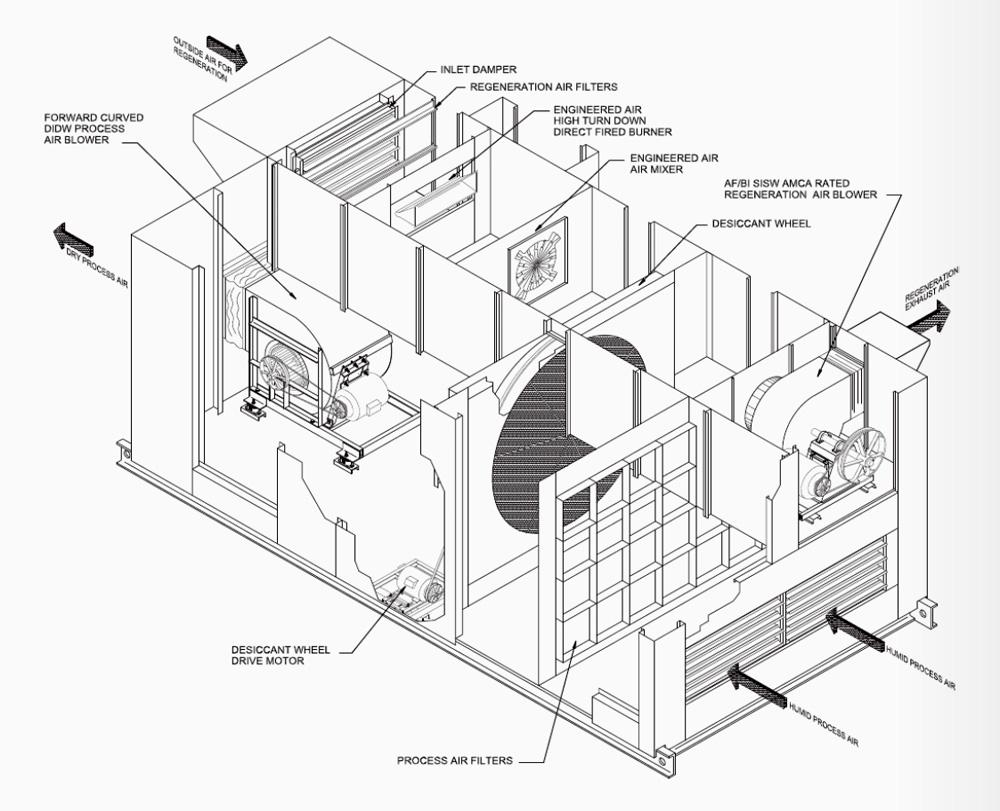

HE/DWD Series Gas Fired Desiccant De-humidification Unit

Features

- Indoor and outdoor models are available.

- 1500 to 15000 CFM process air.

- Lightweight, thermally and chemically stable, high performance and low maintenance desiccant wheels using activated silica gel for effective moisture and adsorption even in low humidity conditions.

- Sizes available to dehumidify the process air below 40°F dewpoint and remove up to 470 lb/hr moisture @ 60°F DB / 90%RH.

- High efficiency Engineered Air 20:1 high turndown Green Burn direct-fired burner used for desiccant wheel regeneration.

- EngA air mixer enhances moisture removal by providing thorough air coverage onto the face of the desiccant wheel.

Applications

- Ice rink

- Critical temperature storage such as library archive storage

- Production lines for pharmaceuticals

- Production lines for plastic products

- Dehumidification at fertilizer plants

- Food drying

- Museum

- Environmental test room

- Powder filling applications

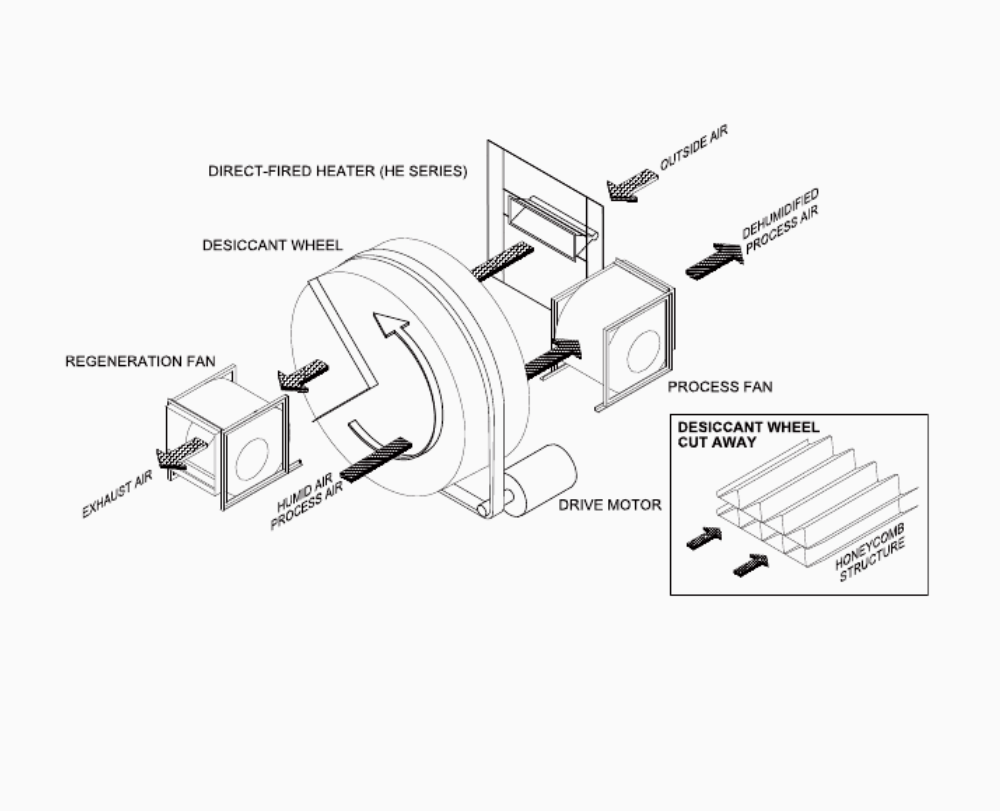

Fundamentals of Operation

- The Engineered Air HE/DWD Series gas fired desiccant dehumidifier uses vapor pressure differential to absorb moisture on the relatively cool process air side and then drive this moisture off in the hot regeneration airstream. The process air is hence dehumidified.

- The desiccant wheel rotates constantly through the process air and the regeneration airstreams.

- The ambient regeneration air is heated by an Engineered Air direct fired burner (HE Series). The water molecules transferred from the process air are then discharged to the ambient.

Benefits

- Gas fired dehumidification units do not have a DX coil and inherent freezing problems associated with a low temperature DX coil. With mechanical cooling dehumidification, the condensed moisture will freeze on the surface of the evaporating coil when the coil surface is below 32°F as is sometimes necessary to reach low dewpoint levels. As a result, the minimum achievable dewpoint is limited by frosting on the DX coil.

- Lower operating cost — especially in areas where the electricity cost is high and the natural gas cost is low. Mechanical cooling compressors require a significant amount of electricity to provide dehumidification.

- No water condensation issues — the mechanical cooling dehumidification evaporator will condense water which will promote undesired microbial growth in the system/

- Lower maintenance cost — gas fired desiccant dehumidifier has fewer components to service than mechanical cooling dehumidification units.

Options

- Mixing boxes can be provided if required.

- Auxiliary Engineered Air cooling components (FW mechanical cooling or chilled water coil) can be added to re-cool dehumidified process air to neutral condition.

- A sensible heat wheel can be added to re-cool the process air down stream of desiccant wheel and preheat the regeneration air upstream of Engineered Air's burner.

- High temperature process exhaust heat (approximately 125°F to 280°F) from the building, steam or electric heat, if available, can be used in the regeneration air to reduce the required heating capacity or eliminate the direct fired burner.

- A cooling coil (DX or chilled water) could be used as an option to re-cool the warm dehumidified air.

View Brochure PDF Request Access to our Complete Catalog

Due to continuous product development, specifications, dimensions and capacities are subject to change without notice.